Concept to Cure

Contract Development & Manufacturing of Medical & IVD Devices

Transform patient care and improve lives with breakthrough innovations empowered by our comprehensive, scalable service solutions. Our 21CFR820-compliant solutions integrate design and development, prototyping and testing, contract manufacturing, global supply chain, and regulatory compliance–for seamless support from concept to commercialization.

Accelerating Innovations with

End-to-End Product Realization Services

Accelerating Innovations

21CFR820-compliant End-to-End Product Realization Services.

Product Design and Development

We deliver end-to-end product design and development services for medical devices, in vitro diagnostic instruments, and life sciences equipment—solving complex workflow automation challenges, accelerating innovation, and streamlining the path to commercialization.

Our multidisciplinary team—including systems, mechanical, electrical, test, manufacturing, firmware, and software engineers—collaborates closely with clients to develop innovative, 21 CFR Part 820-compliant solutions. By applying Agile methodologies within a robust regulatory framework, we rapidly iterate, prototype, and de-risk designs while ensuring full traceability, design verification, and process validation from concept to commercialization. This approach reduces development timelines and facilitates efficient regulatory approvals.

With deep expertise in fluidics, robotics, optics, smart sensors and image processing, precision motion control, thermal management, value engineering, embedded systems, and wireless technologies, we help transform our clients’ most complex workflows into compliant, scalable, market-ready products.

Product Design and Development

Product Design and Development

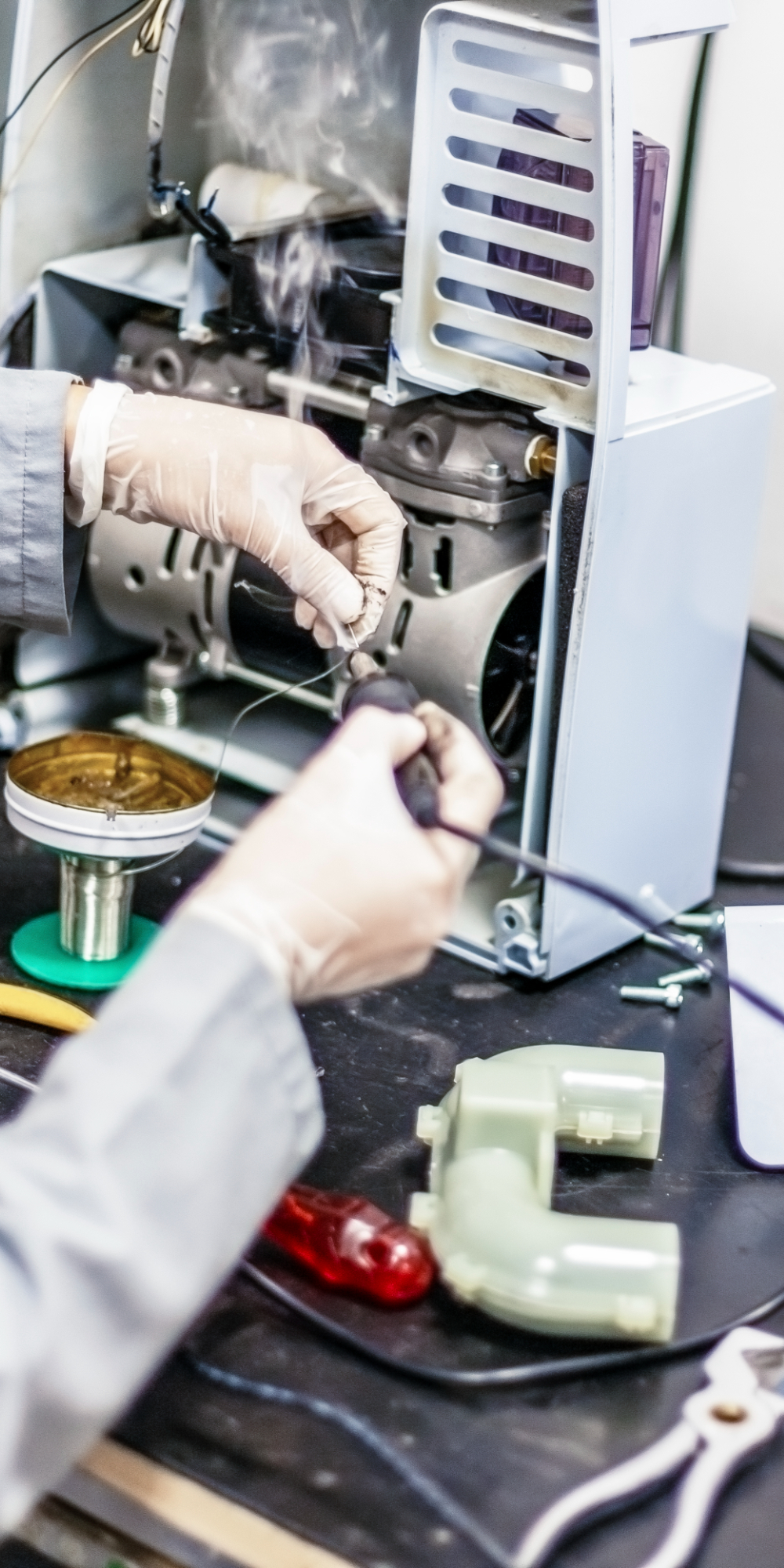

Contract Manufacturing

As an ISO 13485-certified, 21 CFR Part 820-compliant contract manufacturer, we deliver scalable, high-precision production for Class I & II medical devices, diagnostic instruments, and life science equipment. Our end-to-end manufacturing capabilities ensure cost-efficiency, full traceability, quality control, and regulatory compliance.

Services include:

-

Printed Circuit Board Assembly (PCBA)

-

Precision Machining

-

Injection Molding & Tooling

-

Painting & Decoration

-

Electromechanical & Fluidic System Integration

-

Process Validation

We also engineer custom automated equipment for high-throughput reagent and microfluidic consumable manufacturing, including:

-

Assembly & Filling

-

Foil Sealing & Capping

-

Labeling & Barcoding

-

Sterile Packaging Solutions

Our lean, scalable production strategies integrate automated assembly, inline quality control, and just-in-time (JIT) inventory management—delivering repeatable yields, enhanced reliability, and cost optimization, while reducing risk, accelerating commercialization, and ensuring full regulatory compliance.

Contract Manufacturing

Contract Manufacturing

Prototyping and Testing

Accelerate your product development process and ensure consistent performance, compliance, and long-term reliability with our comprehensive prototyping and testing capabilities in our 21 CFR Part 820-compliant, ISO-certified facilities.

In-house labs include:

-

Metrology

-

Electrical

-

Biosafety (BSL-2) & Fluidic

-

ISO-certified cleanrooms

Reliability testing capabilities include:

-

Environmental (Thermal shock, temperature & humidity cycling, ESD, and parametric tests)

-

Mechanical (Vibration, dust, squeeze, drip, drop, button actuation, waterproofing)

-

Paint (Peel-off, cross-cut, sun block resistance, abrasion resistance, and coating)

-

Durability (Chemical exposure, cross-section analysis, red dye penetration, cosmetic, illuminance, acoustic, current stability, keypad actuation, and scratch resistance)

-

Electrical Testing (X-ray inspection, AOI, ICT, and functional testing for PCB assemblies and electronic components including RF, acoustic and antenna. )

Our comprehensive prototyping and testing capabilities accelerate development, reduce risk, and ensure your products meet the highest standards of performance, reliability, and regulatory compliance.

Prototyping and Testing

Prototyping and Testing

Global Supply Chain & Aftermarket Services

We deliver end-to-end supply chain and aftermarket solutions for medical device, biotech, and life sciences OEMs—designed to support scalability, regulatory compliance, and lifecycle performance.

As part of the world’s largest contract manufacturer, our global network of qualified suppliers ensures supply continuity, cost efficiency, and full compliance with 21 CFR Part 820 and ISO 13485. We help OEMs maintain operational excellence in highly regulated environments.

Our 21 CFR Part 820-compliant supplier management processes enhance product quality, patient safety, and traceability—providing transparency and risk mitigation across every stage of the supply chain.

Supply chain solutions include:

-

Multi-source supplier networks

-

Strategic inventory management

-

Real-time demand forecasting

This reduces lead times, prevents disruptions, and optimizes cost while maintaining full compliance.

Aftermarket services include:

-

Repair & refurbishment

-

Spare parts & FRU (Field Replacement Units) management

-

Forward & reverse logistics

So you can extend product lifecycles, minimize downtime, and optimize asset solutions.

We also offer sustainable end-of-life solutions, including responsible disposal and certified recycling, helping OEMs meet environmental and regulatory goals.

Global Supply Chain & Aftermarket Services

Global Supply Chain & Aftermarket Services

Quality and Regulatory Compliance

We ensure that our design and manufacturing services comply with 21 CFR Part 820, helping medical device, life sciences, and biotech OEMs meet regulatory requirements.

Our ISO 13485-certified quality management system (QMS) integrates:

Design for Compliance (DFC)

Process validation (IQ/OQ/PQ)

Statistical Process Control (SPC)

Electronic batch records & real-time deviation tracking

As a 21 CFR Part 820-compliant manufacturer, we meet global standards for safety, risk management, reliability, and regulatory approval through validated, repeatable processes.

We maintain compliance with ISO 13485, ISO 9001, ISO 14001, ISO 45001, IATF 16949, and CTPAT. Our commitment to quality ensures reliability, regulatory compliance, and end-to-end traceability throughout the entire product lifecycle.

Quality and Regulatory Compliance

Medical Device Quality Assurance and Regulatory Compliance

Fluidics & Workflow Automation

Robotics & Automated Handling

Product Design and Development

We deliver end-to-end product design and development services for medical devices, in vitro diagnostic instruments, and life sciences equipment—solving complex workflow automation challenges, accelerating innovation, and streamlining the path to commercialization.

Our multidisciplinary team—including systems, mechanical, electrical, test, manufacturing, firmware, and software engineers—collaborates closely with clients to develop innovative, 21 CFR Part 820-compliant solutions. By applying Agile methodologies within a robust regulatory framework, we rapidly iterate, prototype, and de-risk designs while ensuring full traceability, design verification, and process validation from concept to commercialization. This approach reduces development timelines and facilitates efficient regulatory approvals.

With deep expertise in fluidics, robotics, optics, smart sensors and image processing, precision motion control, thermal management, value engineering, embedded systems, and wireless technologies, we help transform our clients’ most complex workflows into compliant, scalable, market-ready products.

Product Design and Development

Contract Manufacturing

As an ISO 13485-certified, 21 CFR Part 820-compliant contract manufacturer, we deliver scalable, high-precision production for Class I & II medical devices, diagnostic instruments, and life science equipment. Our end-to-end manufacturing capabilities ensure cost-efficiency, full traceability, quality control, and regulatory compliance.

Services include:

-

Printed Circuit Board Assembly (PCBA)

-

Precision Machining

-

Injection Molding & Tooling

-

Painting & Decoration

-

Electromechanical & Fluidic System Integration

-

Process Validation

We also engineer custom automated equipment for high-throughput reagent and microfluidic consumable manufacturing, including:

-

Assembly & Filling

-

Foil Sealing & Capping

-

Labeling & Barcoding

-

Sterile Packaging Solutions

Our lean, scalable production strategies integrate automated assembly, inline quality control, and just-in-time (JIT) inventory management—delivering repeatable yields, enhanced reliability, and cost optimization, while reducing risk, accelerating commercialization, and ensuring full regulatory compliance.

Contract Manufacturing

Prototyping and Testing

Accelerate your product development process and ensure consistent performance, compliance, and long-term reliability with our comprehensive prototyping and testing capabilities in our 21 CFR Part 820-compliant, ISO-certified facilities.

In-house labs include:

-

Metrology

-

Electrical

-

Biosafety (BSL-2) & Fluidic

-

ISO-certified cleanrooms

Reliability testing capabilities include:

-

Environmental (Thermal shock, temperature & humidity cycling, ESD, and parametric tests)

-

Mechanical (Vibration, dust, squeeze, drip, drop, button actuation, waterproofing)

-

Paint (Peel-off, cross-cut, sun block resistance, abrasion resistance, and coating)

-

Durability (Chemical exposure, cross-section analysis, red dye penetration, cosmetic, illuminance, acoustic, current stability, keypad actuation, and scratch resistance)

-

Electrical Testing (X-ray inspection, AOI, ICT, and functional testing for PCB assemblies and electronic components including RF, acoustic and antenna. )

Our comprehensive prototyping and testing capabilities accelerate development, reduce risk, and ensure your products meet the highest standards of performance, reliability, and regulatory compliance.

Prototyping and Testing

Global Supply Chain & Aftermarket Services

We deliver end-to-end supply chain and aftermarket solutions for medical device, biotech, and life sciences OEMs—designed to support scalability, regulatory compliance, and lifecycle performance.

As part of the world’s largest contract manufacturer, our global network of qualified suppliers ensures supply continuity, cost efficiency, and full compliance with 21 CFR Part 820 and ISO 13485. We help OEMs maintain operational excellence in highly regulated environments.

Our 21 CFR Part 820-compliant supplier management processes enhance product quality, patient safety, and traceability—providing transparency and risk mitigation across every stage of the supply chain.

Supply chain solutions include:

-

Multi-source supplier networks

-

Strategic inventory management

-

Real-time demand forecasting

This reduces lead times, prevents disruptions, and optimizes cost while maintaining full compliance.

Aftermarket services include:

-

Repair & refurbishment

-

Spare parts & FRU (Field Replacement Units) management

-

Forward & reverse logistics

So you can extend product lifecycles, minimize downtime, and optimize asset solutions.

We also offer sustainable end-of-life solutions, including responsible disposal and certified recycling, helping OEMs meet environmental and regulatory goals.

Global Supply Chain & Aftermarket Services

Quality & Regulatory Compliance

We ensure that our design and manufacturing services comply with 21 CFR Part 820, helping medical device, life sciences, and biotech OEMs meet regulatory requirements.

Our ISO 13485-certified quality management system (QMS) integrates:

Design for Compliance (DFC)

Process validation (IQ/OQ/PQ)

Statistical Process Control (SPC)

Electronic batch records & real-time deviation tracking

As a 21 CFR Part 820-compliant manufacturer, we meet global standards for safety, risk management, reliability, and regulatory approval through validated, repeatable processes.

We maintain compliance with ISO 13485, ISO 9001, ISO 14001, ISO 45001, IATF 16949, and CTPAT. Our commitment to quality ensures reliability, regulatory compliance, and end-to-end traceability throughout the entire product lifecycle.

Medical Device Quality Assurance and Regulatory Compliance

Concept to Cure -

See how our expertise in automated diagnostic and analytical systems accelerates innovation and streamlines your path to commercialization.

Automating Diagnostic & Analytical Workflows

Unlock High-Performance Engineering Solutions.

-

High-resolution microscopy & quantitative fluorescence imaging

-

AI-powered image analysis & hyperspectral imaging

Concept to Cure -

See how our expertise in automated diagnostic and analytical systems accelerates innovation and streamlines your path to commercialization.

Driving Innovation to Commercialization

Harness our deep domain expertise to accelerate your product realization journey.

Genomics, Sequencing & Multi-Omics Technologies

Sample Preparation & Lab Automation

Synthetic Biology

&

Next-Gen Bioengineering

Cell & Gene Therapy &

Bio-manufacturing

Minimally Invasive Surgery Devices & Surgical Robotic Systems

Neuromodulation & Nerve Stimulation Technologies

Diabetes & Digital

Health Solutions

Drug Delivery &

Wearable Devices

Diagnostic Imaging &

AI-Powered Radiology

Value Engineering

Learn More

Learn more about how our expertise in medical innovation can help you accelerate your product realization journey.

Driving Innovation to Commercialization

Harness our deep domain expertise to accelerate your product realization journey.

-

Flow Cytometry & Cell Sorting Technologies

-

Liquid Biopsy & Automated Sample Handling

Ensuring Compliance, Safety & Quality

A shared commitment to product quality, regulatory compliance, and patient safety throughout the product life-cycle.

Master Control System Platform

A shared commitment to product quality, regulatory compliance, and patient safety throughout the product life-cycle.

Liquid Handling Workflow Automation Platform

A shared commitment to product quality, regulatory compliance, and patient safety throughout the product life-cycle.

.png)

.png)